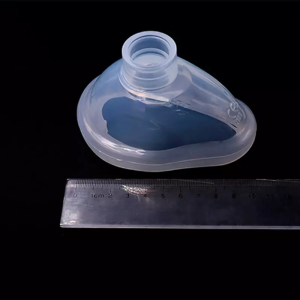

Durable Medical Grade Silicone Breathing Mask for Custom Solution

Silicone Product Specifications:

Tooling Materials:

– Compression Tooling:SL36 Hot Treatment, imported NAK80

– LSR Injection Mold:NAK80

– PVC Injection Mold:718H, S136, NAK80

Mask Materials:

– Silicone:Wacker

– LSR:Wacker, Dow Corning

– PVC

Sizes/Types:

– Neonate, Infant, Pediatric, Adult (0#, 1#, 2#, 3#, 4#, 5#)

Usage:

– Disposable Masks:PVC

– Reusable Masks:Silicone, LSR

Working Temperature:

– LSR Mask:-20°C to 450°C

– Silicone Mask:-40°C to 230°C

– PVC Mask:-10°C to 85°C

Our Competitive Edge:

- In-House Mold-Making Expertise:Established since 1998.

- Direct Manufacturer Pricing:Cost-effective solutions.

- Expert Design Team:Five seasoned designers providing technical, production, design, and artwork support.

- Quality Compliance:Production and testing adhere to ISO 9001 standards.

- Fully Equipped Facility:Comprehensive production plant with advanced equipment and optimal working environment.

Why Choose Us?

- Manufacturing Plants:

– Mold-Making

– Silicone Rubber Compression

– Plastic Injection

– LSR Injection (Class 100,000 clean room)

– Assembly (Class 100,000 clean room)

- Mold-Making Equipment:

– CNC, Mirror EDM, EDM, Slow-Speed Wire Cut, and auxiliary equipment

- Production Equipment:

– 15 rubber compression machines

– 8 Haitian plastic injection machines

– 2 LSR injection machines

- Testing Equipment:

– 3D projectors

– Sealing testers

– Elasticity measurement tools

– Durometers

- Clean Room Environment:

– Class 100,000 dust-free LSR injection machines and assembly line

- Rapid Response:

– Efficient and quick adaptation to customer needs and market demands

Quick Request for Quotation (RFQ) Requirements

- Detailed Product Specifications:

– Provide comprehensive details about the product, including dimensions, materials, and any special features or requirements.

- Quantity Needed:

– Specify the exact number of units required to ensure accurate pricing and production planning.

- Delivery Timeline:

– Indicate the desired delivery date to help assess production scheduling and logistics.

- Budget Constraints:

– Mention any budget limitations to enable tailored quotations that fit within your financial parameters.

- Quality Standards:

– Outline any specific quality certifications or standards the product must meet, such as ISO or RoHS compliance.

- Prototype Requirements:

– State if a prototype is needed before full production to validate design and functionality.

- Additional Services:

– Include any additional services required, such as packaging, labeling, or custom branding